Continuing the Van Conversion

After a 20 night trial run in the van over January we had a few additions/modifications to make. We had developed a mild case of van envy after spending quite a bit of time in Oli and Chris’s van, often going over for a vanquets. We can’t have their additional head room but we could copy their idea of a sink complete with running water fed by an electric pump.

We had previously snubbed the idea of a sink as of course we could make do with a washing up bowl, and fill up our water bottles from the storage containers we kept under the bed. However being able to easily decant and drain away water was a luxury we were willing to work/pay for.

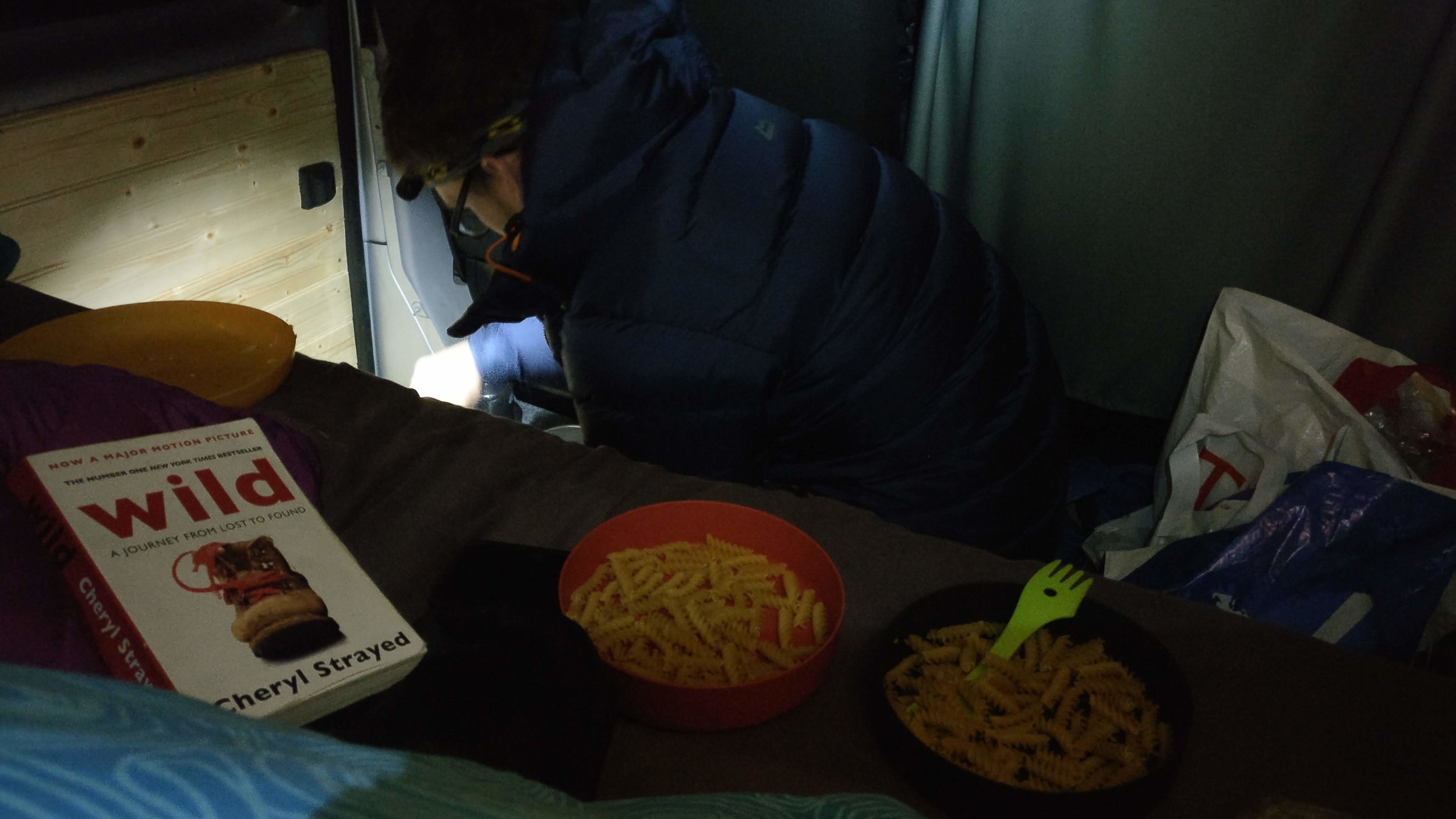

We also deliberated about what style of hob to have as all the cooking we had done in the van was on our small camp stove on the floor. We thought about copying Oli and Chris’s way of getting a family style camping gas hob which isn’t directly attached to the van. However due to our limited space it made sense to get a hob/sink unit.

We had also deliberated about whether or not to get a leisure battery. We had survived in Scotland by only charging our phones whilst we were driving. But we did have to retreat to a pub to charge Olly’s laptop one day. Also with our new sink decision our fancy tap would require electricity for it’s pump.

So after initially deciding to go for a purely minimalistic approach to van converting we spent some time in the van and other peoples vans and due to van envy we decided to go full on with the conversion.

The decision was made and now we had to make lots of other hard adult decisions like; what sink do we want? What gas type do we want? What colour MDF paint shall we buy? and most importantly are we actually competent enough to carry this out?

Difficult decisions made and many stressful trips to B&Q later we had most of the parts and had arrived in Devon with enthusiasm to start work. These persnickety jobs turned out to be rather trying and we often felt like we hadn’t achieved anything all day.

Our different styles of “doing stuff” really became apparent during this stage of the van conversion. I am a planner and like to have the full job planned out far in advance such that we can make one efficient trip to B&Q or make one order online which will arrive in plenty of time. Olly on the other hand is a muller, he likes to think options out throughout the week and then splurge buy what he thinks we need. This worked well before when we still had jobs and there was ample opportunity for mid week mulling time. However, on a tight timescale this was a little more tricky. It’s lucky that next day delivery exists and to be honest its very difficult to buy all the correct things the first time.

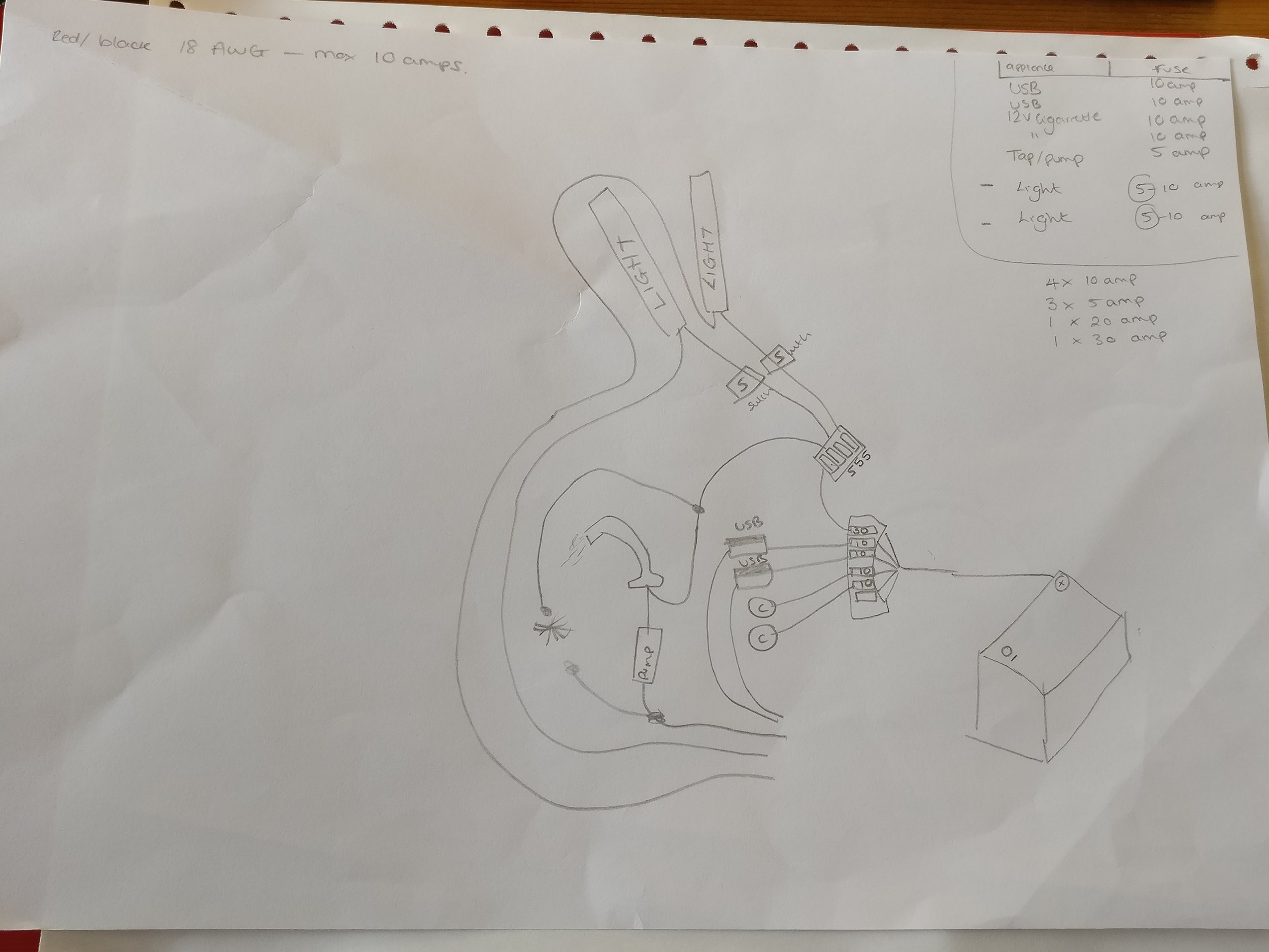

Additionally, I have a annoying habit of leaving Olly in charge of the “complicated stuff” like gas and electricity but then reading many articles and forums, getting paranoid about safety complications then badgering Olly with questions like “have you thought about a gas drop out vent?” “Are you sure those cables are thick enough to take that current?” “Is that definitely not going to catch fire and kill us in our sleep?” And “Is that going to electrocute me?”. In reality I’m totally not qualified to take the safety high horse as I think my last experience of "doing electrics" was at age 8 when I wired up my dolls house with tin foil to a set of AA batteries. I don't think the lights ever worked but the foil got very hot, and the lights were promptly confiscated from said house by my dad. Also see below my first laughable attempt at a circuit diagram which contains many errors.

We had already constructed and installed the bed in the van before Christmas with help from Paul and Thirza, just in the nic of time before going away and actually using it. It held up fine and worked well with our storage boxes sliding underneath.

My first job this time was to finish carpeting the metal areas which were condensation hotspots, meanwhile, Olly removed both the passenger and driver seats to work out where to feed through cables for the leisure battery. This actually turned out to be easier than we thought and we even found some bonus coins down the back of the seat. We also found some bits of pretzel which is alarming considering we have never eaten pretzels in the van...

Olly then made some cladding panels for the back doors, he had just finished them and went to screw them on when he realised he had accidentally made them with vertical panels rather than horizontal. This didn’t actually matter as the double thickness of wood meant they didn’t fit anyway.

Parking this for now we then moved onto making a frame and worktop surround for the sink. We were told it would arrive with a stencil to cut the worktop out, but it didn’t. However we made own with our now well honed stencilling skills.

We next measured and constructed a frame which took a bit of thinking as to which bits to screw together first such that we could still screw in the further bits.

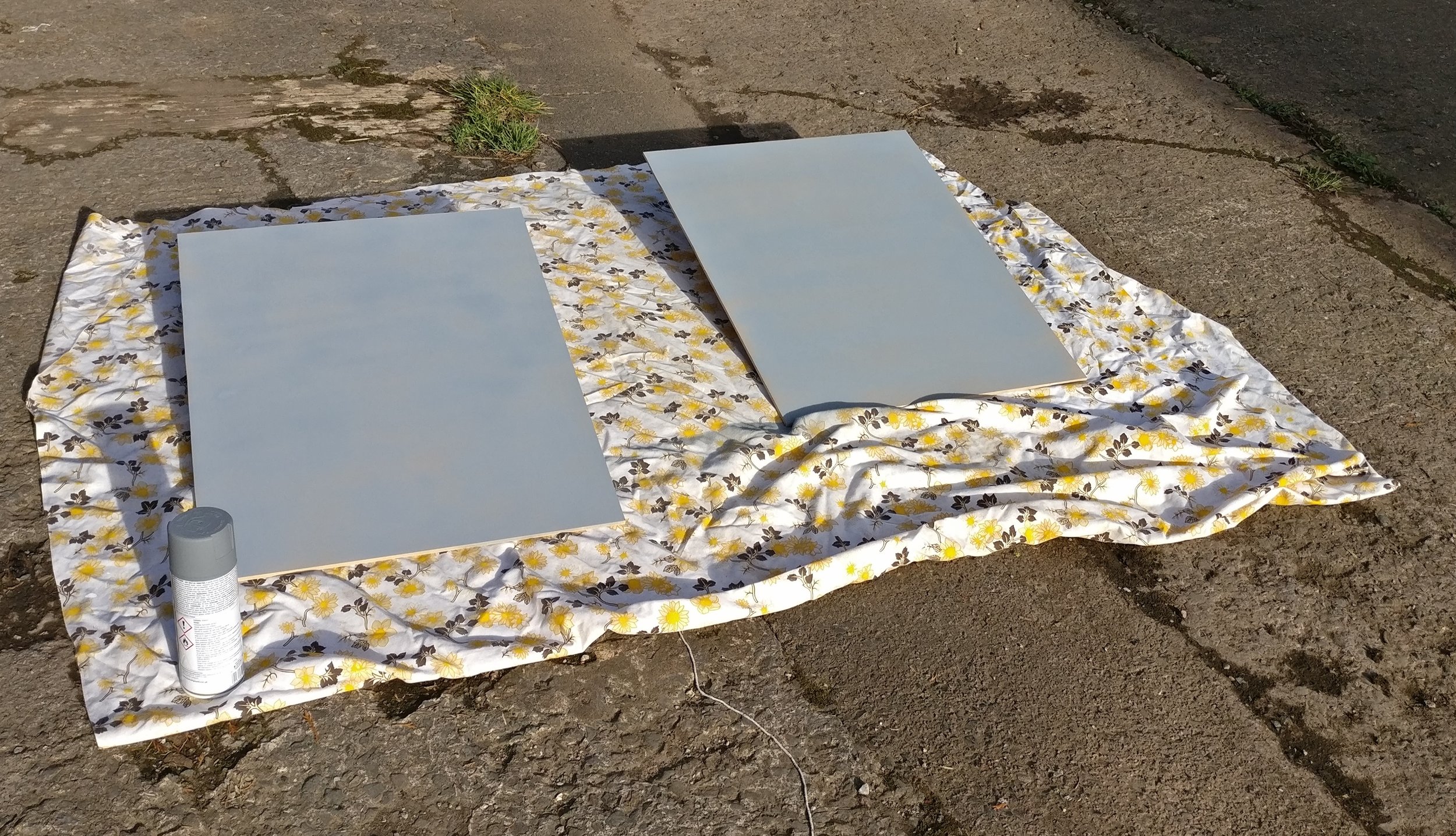

Frame assembled, top attached and treated. The next job was to cut out some MDF sides. We spray painted these with primer (it had taken us half an hour in B&Q to choose the colour), annoyingly they turned out a little patchy probably because you are meant to add a top coat.

We had checked the frame fitted in the van, so we went ahead and screwed on the sides. Obviously we either hadn't accounted for the bulk head screw length or our cabinet wasn't quite square as with the sides on it didn't quite fit.

Luckily 20minutes with a junior hacksaw later and 5 bulk head screws removed it was a perfect tight fit.

The next rather committing job was to drill a hole in the floor of the van for our gas drop out vent. After some research we learned that having a gas locker with vent to outside would ensure that any gas leakage should safely sink and exit through the vent rather than build up inside the van to explosive levels.

This seemed like a simple task but drilling a hole through the van is always rather nerve racking, we measured as best we could to hopefully avoid hitting anything important like the brake lines. In the end we decided to drill a pilot hole from underneath. I watched for the drill bit and was relieved when it poked through approximately where we wanted it to inside the cabinet area.

We then used our new hole saw piece but the battery operated drill did not have enough omph to get through metal. Luckily we managed to borrow a mains drill from a neighbour and we were soon through the floor with all the important car bits still intact.

We then headed to Wales for the weekend, this worked out very well for us as some competent friends helped us install the gas pipe work. Thanks Paul!

We then had the tricky task of wiring up our appliances to our leisure battery. To keep things simple we decided to just use one fuse box and run wires to a "charging box" which would sit at the end of the bed.

We then had a fun day of connecting different coloured wires to different things and though Olly had laughed at my first attempt at a circuit diagram attempt No.2 (which was more accurate) was actually quite useful as we now have a map of which coloured wires go to which things.

Olly then wired up the sparker for our hobs and the switch and pump for the tap. We also had to connect a water and waste pipe to the two storage containers under the sink.

The last bit to do was drill a hole for a battery vent tube. There seems to be mixed advice online about whether a lead acid battery needs venting but we decided to err on the side of caution and follow the manufacturers advice.

Annoyingly the vent tube we purchased wasn't quite long enough. However I had expected this and has scavenged some extra tubing from my parents house. Who would have guessed that keeping a catheter tube because you thought it would come in useful was actually a good idea!

So with our luxury running water and bedside charging facilities we headed off to Pembrokeshire for a test run.